Part:BBa_K3717009

α-Galactosidase with T7 + RBS, N-Terminal 6x His-Tag, and Double Terminator

The composite part utilizes a T7 promoter + RBS (BBa_K525998), α-Galactosidase (BBa_K3717006), and double terminator (BBa_B0015).

α-Galactosidase catalyzes the cleavage of the galactose off of B type blood antigens such that the remaining sugar can be classified as a H antigen, which the anti-A and anti-B antibodies are unable to recognize and hence does not elicit an immune response in the human body [1]. Thus, α-Galactosidase converts B blood types to universal O type.

Figure 1. α-Galactosidase with T7 Promoter, strong RBS, N-Terminal 6x Histidine tag and Double Terminator Construct.

Construct Design

We derived the sequence of α-Galactosidase from Bacteroides fragilis [2] and optimized the sequence for E. coli protein expression. We then attached a 6x Histidine Tag (6x His-Tag) upstream of the α-Galactosidase sequence followed by a glycine-serine linker (GS linker) to form our open reading frame (ORF) (BBa_K3717006) for purification purposes. We flanked our open reading frame with a T7 promoter + RBS (BBa_K525998) upstream of the open reading frame and a double terminator (BBa_B0015) downstream of the sequence. This composite part (BBa_K3717009) was assembled through DNA synthesis by IDT.

Characterization

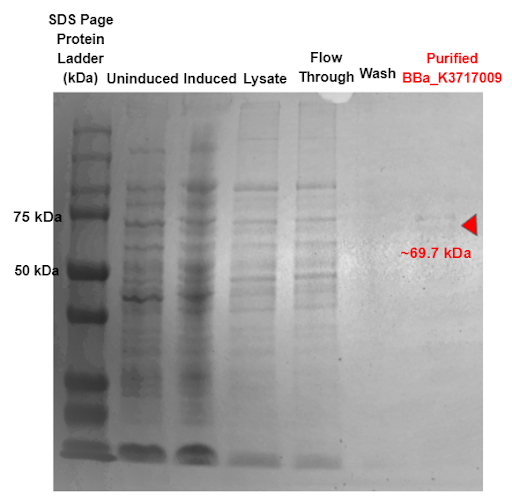

Protein Expression and Purification

We transformed synthesized plasmids into BL21 (DE3) E. coli cells. We grew cultures at 37°C overnight, diluted those cultures, and then grew to OD600 0.5~0.6 at 37°C. We then induced expression with 0.5 mM IPTG and allowed cultures to grow overnight at room temperature. We harvested cells by centrifugation and lysed cell pellets through either sonication or with xTractor Lysis Buffer [3] supplemented with 20 mM imidazole. We purified our histidine-tagged proteins using Ni sepharose affinity chromatography. We then utilized SDS-PAGE to confirm the sizes of purified proteins.

Our results indicate a protein band at roughly 69.7 kDa, which is the molecular weight of our α-Galactosidase enzyme with the 6x His tag and GS linker attached, proving that our α-Galactosidase (Part: BBa_K3717009) was expressed and purified.

Figure 2. SDS-PAGE of purified proteins with the T7 promoter α-Galactosidase expressing construct (BBa_K3717009). Red triangles indicate expected size for the part.

Functional Testing

We confirmed the functionality of α-Galactosidase (α-Gal) using several assays: colorimetric tests, thin-layer chromatography, and mass spectroscopy.

Colorimetric Tests

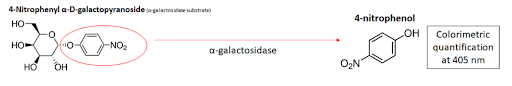

We obtained colorimetric substrates for the enzyme from Sigma Aldrich (Fig 3). This substrate contains a 4-nitrophenol leaving group, which turns yellow upon successful cleavage in solution. The concentration of 4-nitrophenol was quantified at absorbance 405 nm using a 96 well plate based assay [4].

Figure 3. Colorimetric substrate for α-Gal.

We performed small-scale colorimetric tests to verify the function of the enzyme. To each well, we added 50 μL of 10 mM substrate, 10 μL of enzyme, 30 μL of water, and 10 μL of 10x Glycobuffer 1 (50 mM CaCl2, 500 mM sodium acetate, pH 5.5), a buffer recommended by New England Biolabs to ensure optimal enzyme activity [5]. Following 2 hours of reaction at room temperature, we diluted the well contents in 1.9 mL of water and took absorbance readings at 405 nm. Results indicate that α-Gal successfully cleaved its substrates (Fig 4). Moreover, we demonstrated the specificity of the enzyme through the lack of enzyme activity on the other substrate.

Figure 4. Absorbance of reaction solutions in small-scale colorimetric tests verify the functionality and specificity of the enzymes. a) 96-well plates following enzyme reaction. b) absorbance readings of diluted well contents (accounted for dilution). c) buffers and solutions used in substrate and control wells.

To quantify the activity of the enzyme, we performed enzyme reactions at various substrate concentrations and measured the absorbance at different time intervals over a constant time period (Fig 5). Results from at least 3 independent trials for each enzyme were averaged and used to calculate Michaelis–Menten constants for enzyme efficiency (see enzyme model in modeling). The colorimetric substrate tests show that the functionality of our α-Galactosidase part is successful.

Figure 5. Absorbance over time for various α-Gal substrate concentrations

Thin Layer Chromatography

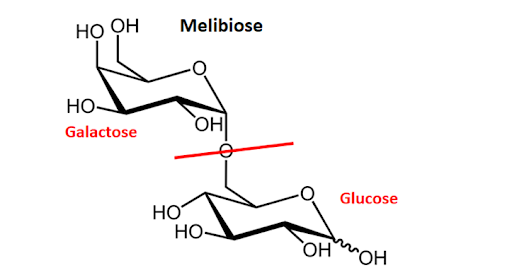

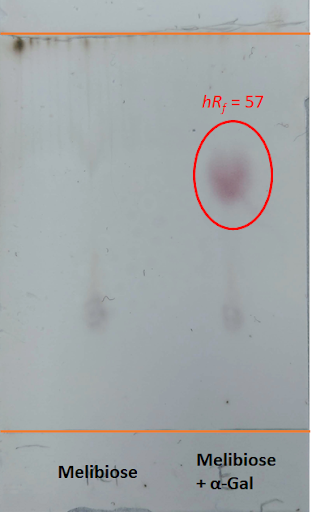

In order to evaluate the enzymatic activity of α-Gal, we used melibiose as the substrate for enzyme reactions followed by detection through normal-phase thin-layer chromatography (TLC), which utilizes the competition of the solute and mobile phase for binding sites to separate compounds based on affinity. α-Gal can cleave the bonds in melibiose, causing the dissolution of melibiose into its constituent monosaccharides, glucose and galactose (Fig 6).

Figure 6. Molecular structure of melibiose. Enzymatic cleavage of glycosidic linkage results in glucose and galactose monosaccharides.

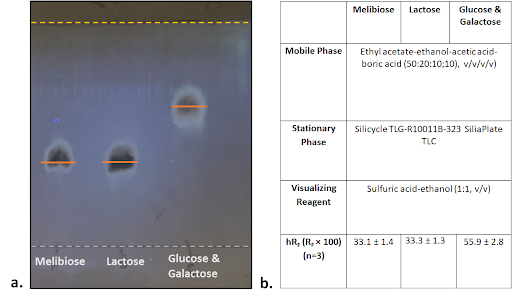

We detected the cleavage of the disaccharides through TLC. To determine if cleavage occurred, we devised a method to test if the disaccharides were present in solution, or if only galactose and glucose product was present, indicating complete cleavage.

To test our method, we spotted controls of melibiose, lactose, as well as glucose and galactose samples onto TLC plates then run with a mobile phase of ethyl acetate : ethanol : acetic acid : boric acid (5:2:1:1, v/v/v/v) (Fig 7). We visualized the plate with a spraying reagent consisting of sulfuric acid : ethanol (1:1, v/v), followed by heating at 140°C for 5 minutes. We observed bands both in ambient light and at 365 nm, and we measured Rf values as the solute front (orange line) divided by the solvent front (yellow line). Based on our experiments, we were able to determine that glucose and galactose migrate significantly further up the plate compared to lactose and melibiose, with hRf values of 55.9 ± 2.8 for glucose and galactose, 33.3 ± 1.3 for lactose, and 33.1 ± 1.4 for melibiose.

Figure 7. Simultaneous TLC of melibiose, lactose, and glucose with galactose controls. a) Visualized plate at 365 nm. b) TLC parameters used and averaged hRf values calculated.

With our TLC detection method in place, we proceeded to test the functionality of α-Gal. We incubated 10 μL of 10 mg/mL melibiose with 5 μL of enzyme or water (negative control) and 5 μL of 0.1 M citrate-phosphate buffer (pH 5.8) at room temperature for a total reaction time of 2 hours (Takasaki 1975). We then spotted the control and enzyme reaction sample on TLC plates and developed them using the predetermined (see above) TLC parameters and visualization steps (Fig 8). Our results demonstrate successful cleavage of its substrate by α-Gal, as indicated by the band with a hRf that corresponds approximately to the measured hRf of glucose and galactose.

Figure 8. TLC plate of melibiose treated with water and α-Gal under ambient light. There is clear cleavage of melibiose into glucose and galactose from the enzyme reaction.

Mass Spectroscopy Trisaccharide Antigen Tests

Given that the colorimetric results were positive, we wanted to further test the enzymes’ specificity by using trisaccharides as substrates. These trisaccharides contain three monosaccharides that have identical chemical structures to the A and B antigens found on RBCs. To test a proof of concept functionality of α-Gal in cleaving the B-antigen trisaccharide and NAGA in cleaving the A-antigen trisaccharide, we carried out a reaction of the enzyme and its corresponding trisaccharide dissolved in 1X GlycoBuffer [4], deionized water, and purified BSA for 1 hour at 37°C. A-antigen and B-antigen trisaccharides were kindly supplied by Professor Dr. Todd Lowary from the Institute of Biological Chemistry at Academic Sinica [6].

For each enzyme, a non-specific trisaccharide served as a negative control and the trisaccharide specific to the enzyme served as the experimental unit (Table 1).

Table 1. Experimental setup for enzyme-antigen tests.

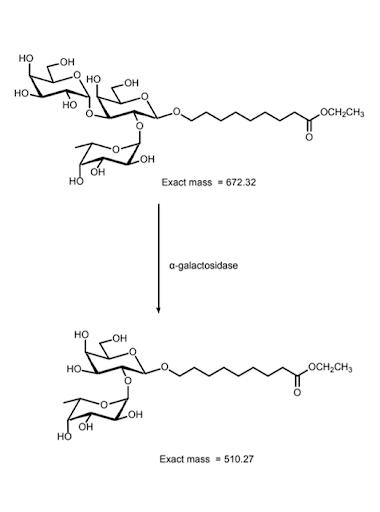

After the reaction, the reaction solution was passed through C18 columns to minimize impurities from the reaction solution. We then evaluated the flow through solution with a mass spectrometer to measure peaks in molar mass in order to determine the compounds present in the reaction solution. The original molar mass of the B-antigen is 672.32g/mol; therefore, after cleavage, two fragments with molar masses of 510.27g/mol and 162.05g/mol are expected to form (Fig 9).

Figure 9. Molecular structure and mass of B-antigen trisaccharides and subsequent products following enzymatic cleavage.

The results shown by the mass spectrometer confirm the functionality of α-Galactosidase. The experimental unit shows the presence of the cleaved fragment from the reaction with the B-antigen trisaccharide, indicated by the peak at 533 g/mol in the mass spectrum (Fig 10). The negative control confirms the specificity of α-Gal, as the A-antigen trisaccharide was not cleaved, indicated by the peak at 736 g/mol (Fig 11). Throughout all readings of the mass spectrum, the molar mass of the peaks have been increased by 23 g/mol due to a sodium adduct. Unrelated peaks/background noise can be attributed to compounds present in the buffer solution.

Figure 10. α-Gal cleaves B-antigen trisaccharide. Mass spectrum of α-Gal and B-antigen trisaccharide reaction solution (experimental unit, flow through). The peak at 533g/mol shows the presence of the cleaved fragment from the reaction of the α-Gal enzyme and B-antigen trisaccharide.

Figure 11. Negative Control: Mass spectrum of α-Gal and A-antigen trisaccharide reaction solution (negative control, flow through). The negative control confirms the specificity of α-Gal, as the A-antigen trisaccharide was not cleaved, indicated by the peak at 736g/mol.

Mass spectroscopy results from the reaction between α-Galactosidase with B-antigen trisaccharide substrate demonstrate its ability to cleave its specific trisaccharides, demonstrating the proof of concept that the enzyme is able to cleave the B blood group antigens.

References

1. Rahfeld, Peter, and Stephen G. Withers. “Toward Universal Donor Blood: Enzymatic Conversion of A and B to O Type.” Journal of Biological Chemistry, vol. 295, no. 2, Jan. 2020, pp. 325–34. DOI.org (Crossref), https://doi.org/10.1074/jbc.REV119.008164.

2. UniProtKB - Q5LIM3 (Q5LIM3_BACFN). UniProt, 2 June 2021, www.uniprot.org/uniprot/Q5LIM3. Accessed 20 Oct. 2021.

3. XTractorTM Buffer & xTractor Buffer Kit User Manual. (n.d.). 10.

4. Held, Paul. “Kinetic Analysis of β-Galactosidase Activity Using the PowerWave™ HT and Gen5™ Data Analysis Software .” BioTek, 16 Feb. 2007.

5. Biolabs, New England. “Typical Reaction Conditions for α-N-Acetylgalactosaminidase (P0734).” New England Biolabs: Reagents for the Life Sciences Industry, https://international.neb.com/protocols/2013/01/10/typical-reaction-conditions-p0734.

6. Meloncelli, Peter J., and Todd L. Lowary. “Synthesis of Abo Histo-Blood Group Type I and II Antigens.” Carbohydrate Research, vol. 345, no. 16, 16 Sept. 2010, pp. 2305–2322., https://doi.org/10.1016/j.carres.2010.08.012.

Sequence and Features

- 10COMPATIBLE WITH RFC[10]

- 12COMPATIBLE WITH RFC[12]

- 21COMPATIBLE WITH RFC[21]

- 23COMPATIBLE WITH RFC[23]

- 25INCOMPATIBLE WITH RFC[25]Illegal AgeI site found at 246

Illegal AgeI site found at 549 - 1000COMPATIBLE WITH RFC[1000]

| None |